Digital Fabrics for 3D Clothing Simulation

-

Understanding 3D Clothing Simulation

To create accurate and true-to-life 3D digital garments, it is crucial to simulate and visualize fabrics realistically. This involves understanding the fabric's nature and closely mimicking its drape and behavior in the digital environment.

Key Components of 3D Clothing Simulation:

- Digital Pattern (DXF format): The blueprint of the garment, detailing the design and structure.

- Avatar/s: Digital models that represent the human form, used to fit and visualize the garments.

- Digital Fabrics: Virtual representations of fabrics that mimic real-world material properties.

The simulation process not only creates visually appealing digital garments but also captures the material's physical characteristics, allowing for accurate drape simulation. This capability is essential for designers to communicate their design intentions effectively to production teams without needing physical samples.

Digital Fabrics: The Backbone of Realistic Simulation

Digital fabrics are composed of two main properties:

-

Physical Properties: These include fabric thickness, bending, shear, tensile strength, and friction, all of which determine how the fabric will drape and move in the digital environment. These properties are measured using specialized fabric testing kits, with each 3D software provider having its proprietary methods.

-

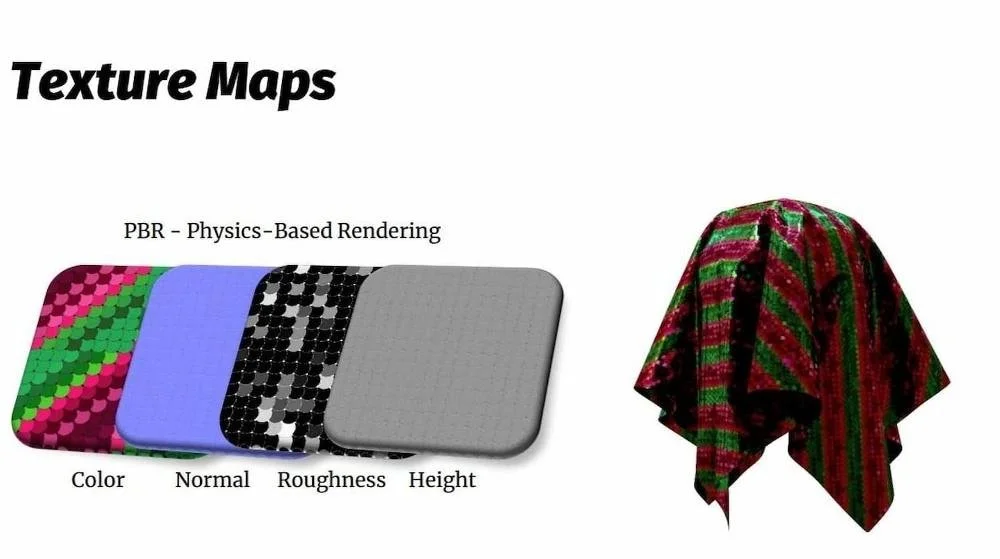

Texture Properties: These are captured using sophisticated scanners to create PBR (Physically Based Rendering) texture maps, which give the fabric its visual realism. Tools like Adobe Substance are commonly used for creating fabric textures.

Challenges in 3D Digital Fabrics

Despite the advancements, several challenges persist:

- Lack of Standardization: Different 3D systems use various fabric testing methods, file configurations, and data formats, leading to inconsistencies in simulation results across platforms.

- Diverse Fabric Types: The wide variety of fabrics used in the apparel industry complicates the process of achieving consistent and accurate digital representations.

Efforts are being made to create a standardized testing method, which would allow for universal fabric physics data. This would greatly enhance the accuracy of digital garments and facilitate better communication among designers, manufacturers, and vendors.

3D CLOTHING SIMULATION STRUCTURE

-

Challenges in 3D Digital Fabrics

Despite the advancements, several challenges persist:

- Lack of Standardization: Different 3D systems use various fabric testing methods, file configurations, and data formats, leading to inconsistencies in simulation results across platforms.

- Diverse Fabric Types: The wide variety of fabrics used in the apparel industry complicates the process of achieving consistent and accurate digital representations.

Efforts are being made to create a standardized testing method, which would allow for universal fabric physics data. This would greatly enhance the accuracy of digital garments and facilitate better communication among designers, manufacturers, and vendors.

The Push for Unified Digital Fabrics

The development of a universal 3D fabric file format, like U3M (Unified 3D Material), aims to bridge the differences among 3D systems. If widely adopted, U3M could standardize the way digital fabrics are simulated across different platforms, significantly advancing the digitization of the apparel industry.

Digital Fabric Libraries: A Growing Necessity

With the integration of 3D technologies, the demand for digital fabric libraries is increasing. Platforms like Swatchbook, Material Exchange, and CottonWorks offer extensive digital fabric libraries that enhance the efficiency and consistency of 3D simulations.

Conclusion

While 3D clothing visuals have emerged as powerful marketing and selling tools, the industry still faces challenges in improving fit and sizing. However, as 3D technology continues to evolve, the implementation of standardized fabric testing and unified digital file formats will likely lead to significant gains in production efficiency and the overall digitization of the apparel industry.

.jpg)